What is Dye Sublimation Printing? What are its advantages?

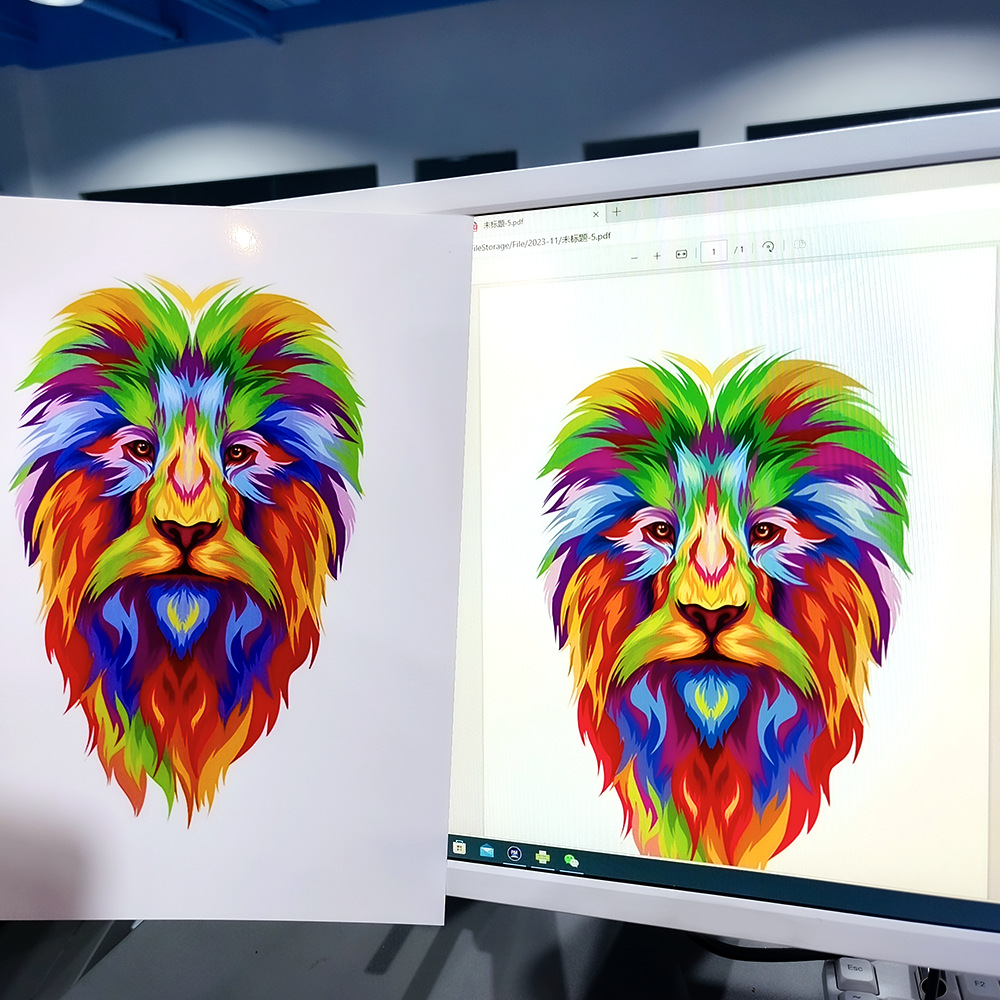

Dye sublimation printing, also known as Heat sublimation printing or Thermal sublimation printing, is a digital printing process that uses heat to transfer dye onto materials such as fabric, plastic, or paper. This method offers high definition and vivid prints with excellent color reproduction and clear details. Let’s explore the characteristics, advantages, disadvantages, and applications of dye sublimation printing.

Characteristics of Dye Sublimation Printing:

Thermal sublimation printing works by converting solid dye into a gas without passing through a liquid state, a process known as sublimation. More specifically, it prints dye directly onto the fabric surface, and then through heat and pressure, the dye is absorbed into the fabric fibers, resulting in vibrant, long-lasting, and realistic patterns.

Advantages of Thermal sublimation printing:

Vivid and Detailed Prints: Heat sublimation printing produces high-resolution prints with smooth color transitions and sharp details.

Durable and Long-lasting: The printed images are resistant to fading, scratching, and washing, making them ideal for textiles and products requiring frequent use.

Versatile Application: Thermal sublimation printing can be applied to various materials, including polyester fabrics, ceramics, metals, plastics, and more.

High printing efficiency: Dye-sublimation can achieve on-demand printing on the same day, without the need for plate making, high flexibility and reduced waste.

Environmentally Friendly: Dye Sublimation Printing uses minimal waste and environmentally friendly dyes compared to traditional printing methods.

Disadvantages of Dye Sublimation Printing:

Limited to Specific Materials: Dye-sublimation works best on polyester-based materials, but it doesn’t work well with natural fabrics like cotton or materials that lack the necessary polymer coating.

Cost of Equipment: Specialized dye-sublimation printers and equipment can be more expensive compared to standard inkjet or laser printers.And it cannot print items that are too large in size.

Complexity with Dark Fabrics: Heat sublimation printing is less effective on dark-colored fabrics, as the dyes used are typically transparent and may not show up well on darker backgrounds.

Applications of Heat Sublimation printing:

Apparel and Textiles: Dye-sublimation is widely used for custom apparel, sportswear, fashion garments, banners and flags.

Signs and logos: Thermal sublimation printing can be used to make signs, labels and signage. Both outdoor and indoor signs can be used.

Home Decor: It’s used for creating personalized home decor items like cushions, curtains, and blankets.

Promotional Products: Dye-sublimation is ideal for producing customized promotional items such as mugs, phone cases, mousepads, and keychains.

Photography: Professional photographers use dye-sublimation for producing high-quality prints, photo panels, and photo gifts.

Certificate and cards: ID cards, membership cards, business cards and other documents and cards can also be produced using sublimation printing technology.

In summary, dye sublimation printing provides various industries with a high-quality, personalized and diverse printing option, meeting the demand for unique and customized products. While it has limitations in terms of material compatibility and equipment cost, its ability to produce vibrant and long-lasting prints remains a popular choice for custom prints across a variety of industries.