How To Distinguish Quickly Between PVC and PP Material?

In different fields, people commonly use PVC and PP material. The primary differences between PP and PVC lie in their appearance, feel, and usage. People can use PVC to make PVC Celuka Board and PVC Free Foam Board, and they can use PP in PP Hollow Sheet.

What is PVC:

The full name of PVC is Polyvinyl chloride(or just simply referred to vinyl), which is a popular thermoplastic material in several industries, just like PP materials.

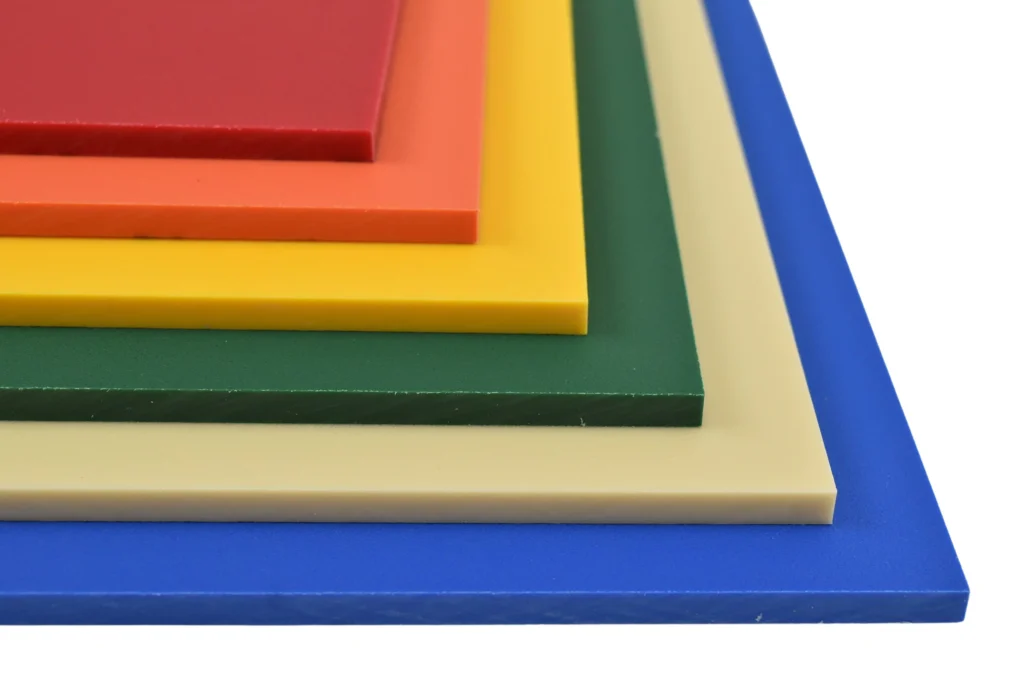

PVC comes in two forms: a rigid form and a flexible form. Rigid PVC is used in construction for pipe, doors and windows, and it is usually used to make PVC Celuka Board and PVC Free Foam Board. Flexible PVC is used in plumbing, electrical cable insulation, flooring, signage, phonograph records, inflatable products, and in rubber substitutes.

PVC contains several key attributes, making it a versatile and widely used material in various industries. First of all, PVC is popular because its durability and resistance to abrasion, making it suitable for long-term applications. Secondly, PVC has good tensile strength so that can withstand mechanical stress. Thirdly, PVC is resistant to a variety range of chemicals, acids and other corrosive substances.

What is PP:

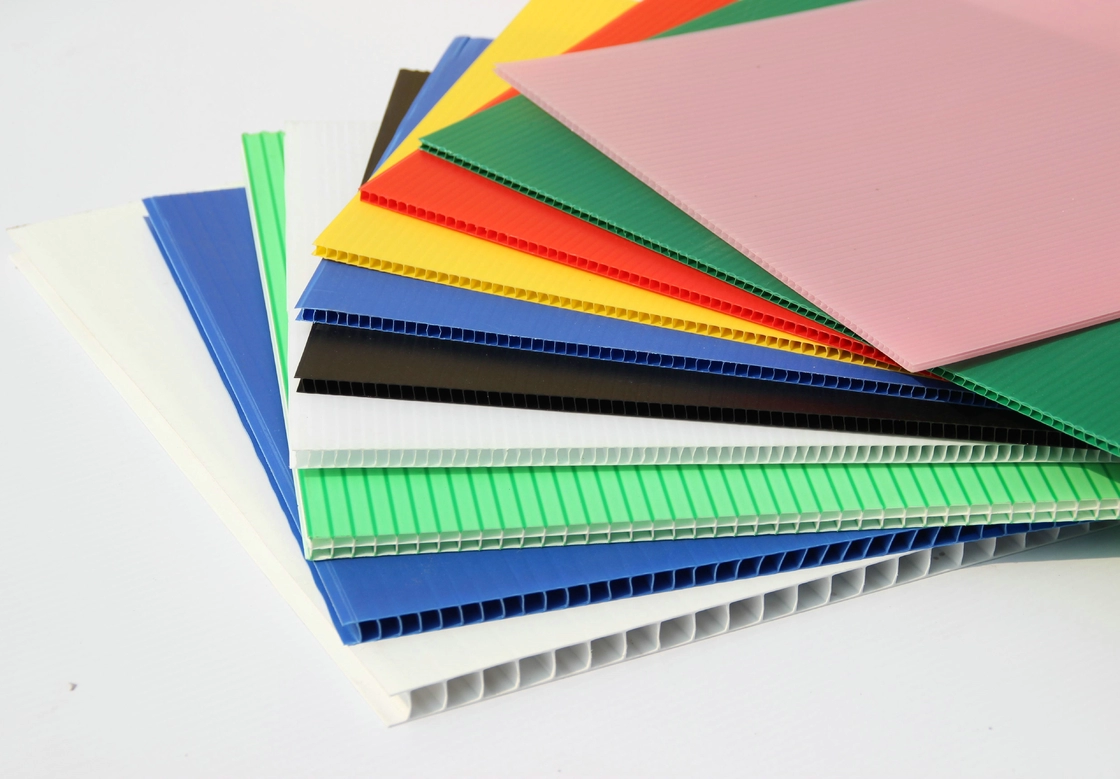

The full name of PP is Polypropylene, a thermoplastic material consists of propylene monomers, and one of the most commonly used thermoplastics in the world today. PP usually used to fabricate various products like PP Hollow Sheet, using thermoplastic manufacturing methods such as injection molding, extrusion, and thermoforming. The density is 0.89 ~ 0.91g/cm3, and it should be used at a temperature range between -30 ~ 140℃.

The full name of PP is Polypropylene, a thermoplastic material consists of propylene monomers, and one of the most commonly used thermoplastics in the world today. PP usually used to fabricate various products using thermoplastic manufacturing methods such as injection molding, extrusion, and thermoforming. The density is 0.89 ~ 0.91g/cm3, and it should be used at a temperature range between -30 ~ 140℃.

PP has excellent chemical resistance, and that makes it a very suitable material for packaging liquids. This kind of material also has insulating properties, so products using PP are less prone to static electricity generation.

PP is mainly appearing in machinery and automobile manufacturing parts, electronic industrial devices, construction, agriculture, fisheries, food industry, textile industry, and printing industry.

The obvious differences are:

1: The difference between PVC and PP Material is obviously different from the appearance or the feel. PP feels hard, PVC is relatively soft. And the easiest way to test is: Burn these two materials with an open flame; if there is black ash, it is PVC, while PP does not produce any. Another way is: You can also differentiate PVC and PP Material by the smell; PVC has a pungent odor, while PP is odorless.

2: PP material is not transparent and people commonly use it in colors such as natural, beige, porcelain white, and milky white. PVC comes in a variety of colors, including gray, light gray, white, yellow-white, and transparent.

3: PP boards have a lower density than PVC boards; PVC has a higher density, so PVC is relatively heavier and stiffer.

4: PP boards are primarily used in acid and alkali-resistant equipment, environmental protection equipment, waste water and exhaust emission equipment, scrubbers, clean rooms, semiconductor plants, and related industrial equipment. PVC boards are mainly appearing in various industries such as construction, packaging, pharmaceuticals, etc. For example, in construction, electroplating equipment, acid and alkali-resistant equipment, industrial pollution control equipment, and the chemical industry.