Specification:

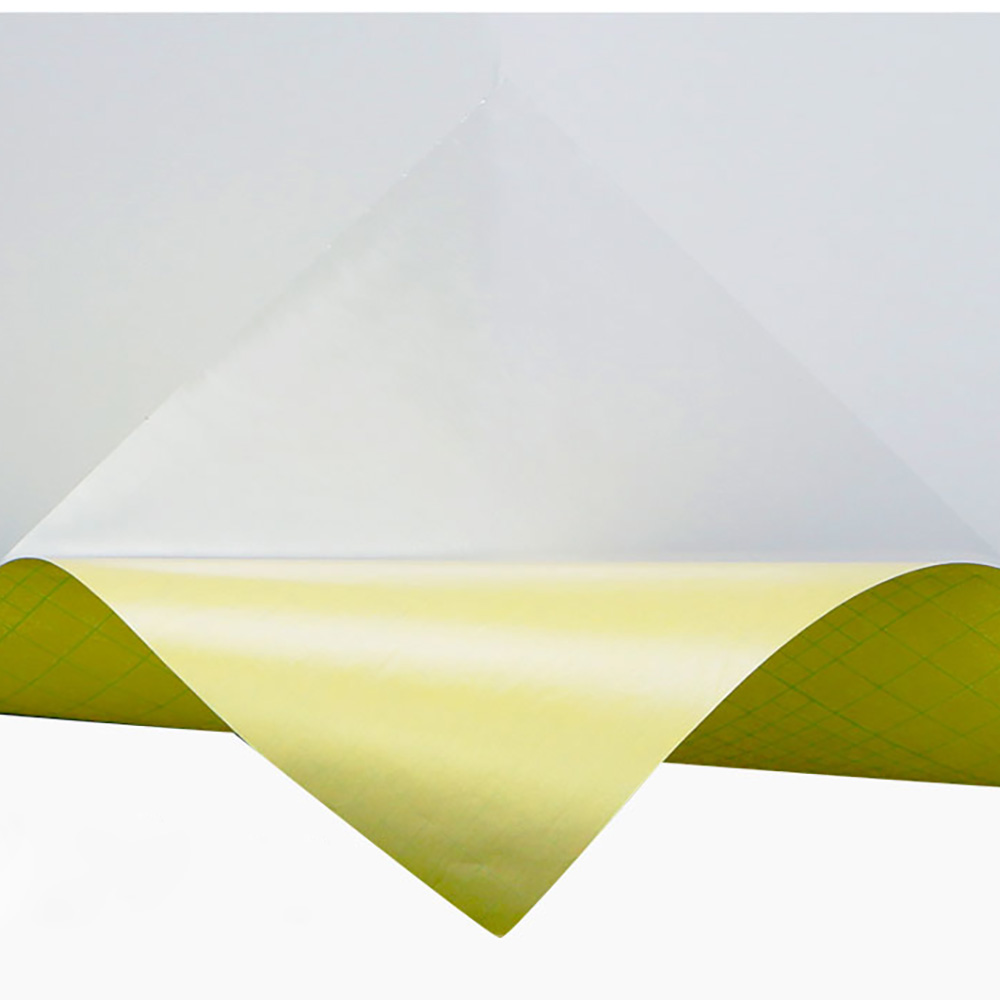

| • Model number: CL217 | • Material: PVC |

| • Surface: Gloss grain | • Hardness: Soft |

| • Transparency: Transparent | • Feature: Moisture Proof |

| • Thickness: 120mic+5mic | • Backing paper: Yellow |

| • Glue thickness: 25mic, Permanent | • Processing Type: Blow Molding |

| • Packing: Carton & Neutral Packing | • Size: 0.914/1.07/1.27/1.37/1.52m*50m |

| • Application: Outdoor/indoor advertising |

Cold and hot laminating films are two different methods of applying a protective layer to printed materials or documents. Here’s a breakdown of the differences between cold and hot laminating film:

Cold Laminating Film:

1. Application Method: Cold laminating film is applied using pressure-sensitive adhesives or self-adhesive backing. It does not require heat or any special equipment for application. It is often referred to as “peel-and-stick” or “self-adhesive” laminating film.

2. Temperature: As the name suggests, cold laminating film does not require heat. It can be applied at room temperature or with minimal pressure, using a laminating machine or by hand. This makes it a safer and more convenient option, especially when working with heat-sensitive materials.

3. Speed: Cold laminating film application tends to be quicker compared to hot laminating. There’s no need to wait for the laminator to heat up, making it a faster process for smaller-scale laminating projects.

4. Material Compatibility: Cold laminating film is suitable for a wide range of materials, including heat-sensitive documents, photographs, inkjet prints, or items that may be damaged by heat. It provides a protective barrier without altering the appearance or colors of the printed materials.

5. Initial Adhesion: Cold laminating film typically offers instant adhesion upon application. This allows for repositioning or adjustments before the adhesive sets, ensuring accurate alignment and reducing the chance of bubbles or wrinkles.

Hot Laminating Film:

1. Application Method: Hot laminating film requires a laminator machine equipped with heated rollers. The film is applied to the printed material, and the laminator uses heat and pressure to activate the adhesive and bond the film to the substrate.

2.Temperature: Hot laminating film requires heat to activate the adhesive and achieve a secure bond. The laminator machine heats the film, typically between 200-300 degrees Fahrenheit (90-150 degrees Celsius), allowing the adhesive to melt and bond with the substrate.

3.Speed: Hot laminating film application may take longer due to the time required for the laminator to reach the desired temperature. However, the actual laminating process is generally faster than applying cold laminating film.

4.Material Compatibility: Hot laminating film is suitable for a wide variety of materials, including paper, cardstock, photographs, posters, and more. However, it is not recommended for heat-sensitive materials or items that may be damaged by the high temperatures involved.

5. Enhanced Protection: Hot laminating film provides a stronger and more durable bond compared to cold laminating. The heat activates the adhesive, ensuring a secure and long-lasting encapsulation of the printed material, protecting it from moisture, UV rays, and physical damage.

It’s worth noting that the choice between cold and hot laminating film depends on the specific requirements of your project. Consider factors such as material sensitivity, desired speed, level of protection, and available equipment when deciding which method to use.